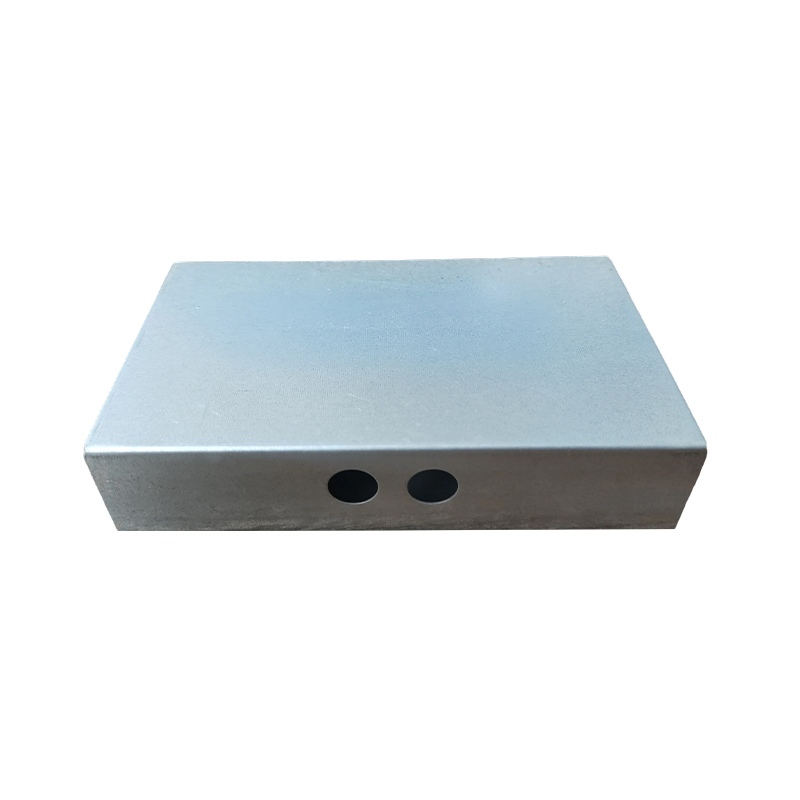

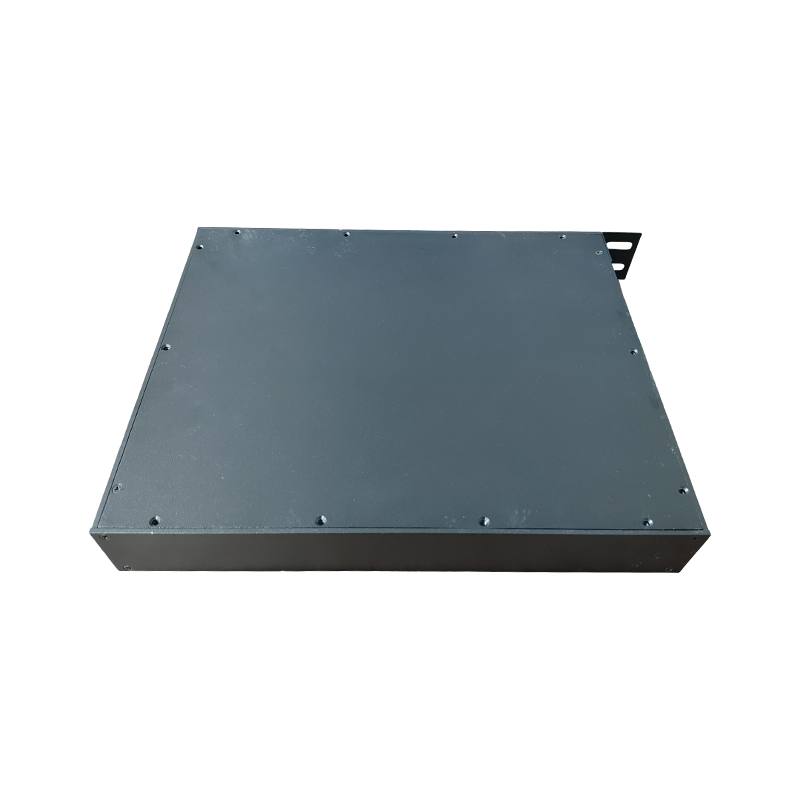

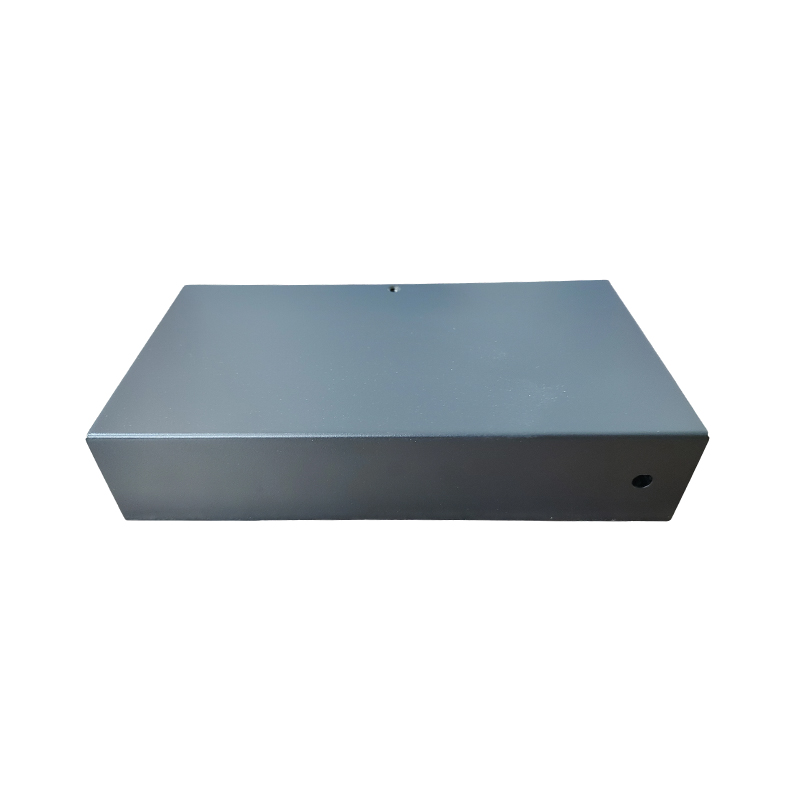

During CNC hardware processing of switch enclosures, the accuracy of the mounting holes and interfaces directly determines whether the product can be assembled smoothly, operate stably, and meet subsequent usage requirements.

- +86-13530196692+86-13613031820

- 844358993@qq.com

- No. 39, Yonglian Road, Longfeng Gonglian Management District, Huicheng District, Huizhou City