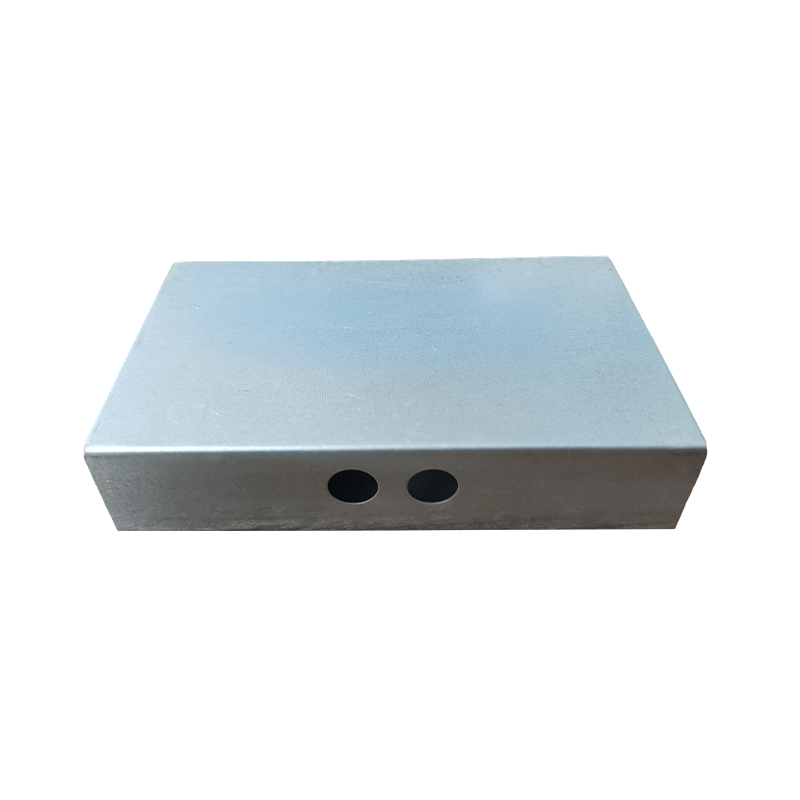

CNC machining, with its digital control and multi-axis linkage capabilities, demonstrates unparalleled efficiency and precision advantages in manufacturing complex curved surface metal housings.

- +86-13530196692+86-13613031820

- 844358993@qq.com

- No. 39, Yonglian Road, Longfeng Gonglian Management District, Huicheng District, Huizhou City