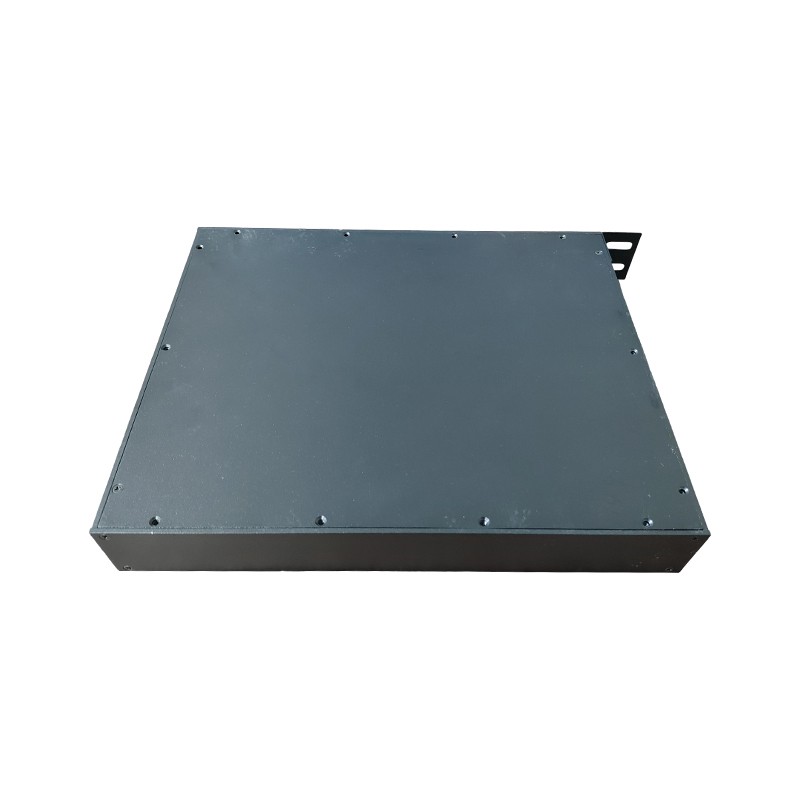

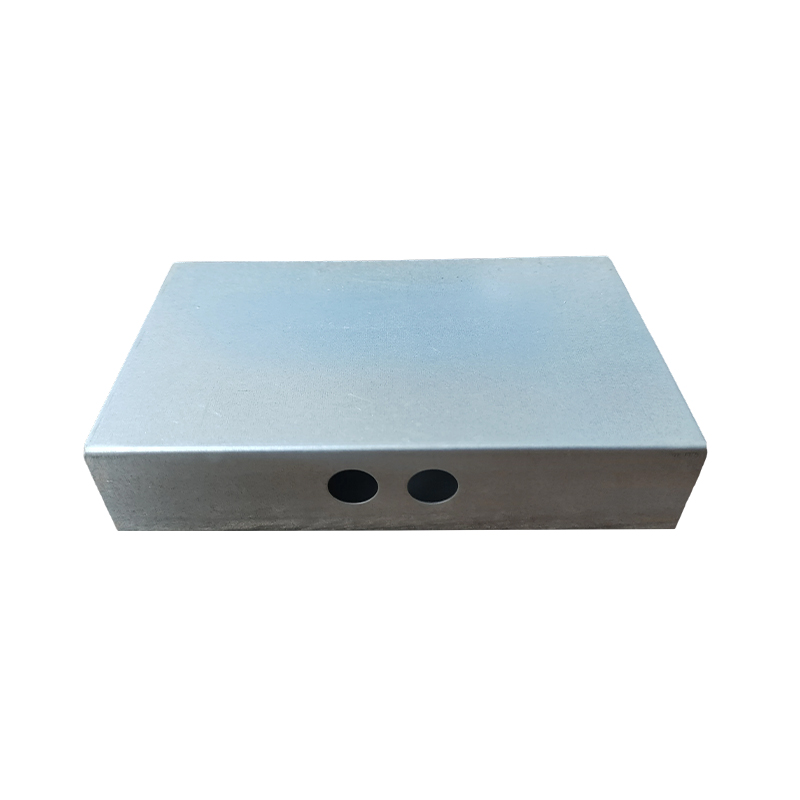

The small metal box manufactured using CNC hardware processing, with its three core advantages of corrosion resistance, impact resistance, and non-deformation, is becoming the preferred solution for high-end industrial hardware casings.

- +86-13530196692+86-13613031820

- 844358993@qq.com

- No. 39, Yonglian Road, Longfeng Gonglian Management District, Huicheng District, Huizhou City